A Budget-Friendly Alcohol Swab Pad Machine for Effective Production is the VIPPAI VPD-250D.

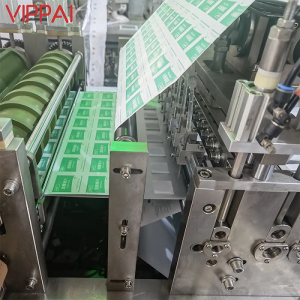

The VIPPAI VPD-250D Alcohol Swab Pad Machine is a low-cost option created to simplify the manufacturing of transportable wipes with a four-side seal and a right angle packing bag. This cutting-edge machine gives companies a dependable and quick way to produce premium alcohol swab pads. Let’s examine the VIPPAI VPD-250D’s main characteristics and advantages to see how it can improve your production procedures.

Operation that is intelligent and effective

A Japanese Yaskawa Servo Motor and Motion Controller are included in the VIPPAI VPD-250D alcohol swab pad machine, assuring increased productivity and intelligent operation. This machine maximises production efficiency without sacrificing quality, moving 100–150 bags per minute.

Flexible Output Options and Folding Features

The VIPPAI VPD-250D alcohol swab pad machine offers businesses the option to choose between single or double pack output, allowing manufacturers to adapt to different packaging requirements based on their target markets. Additionally, the machine features versatile non-woven fabric folding capabilities, accommodating up to 10 vertical folds and 4 horizontal folds. This flexibility enables businesses to cater to specific industry needs and deliver customized solutions to their customers.

Packaging that is secure and leak-proof is sealed twice with heat

The VIPPAI VPD-250D alcohol swab pad machine uses a twice-heated sealing mechanism to assure safe and leak-proof packing. The alcohol swab pads are guaranteed to be intact thanks to the double sealing technique, which also stops any liquid leakage and maintains the wipes’ quality. Businesses can increase consumer happiness and establish a reputation for dependability by maintaining the items’ efficiency and freshness.

Conclusion

The VIPPAI VPD-250D Alcohol Swab Pad Machine is an economical method for producing portable wipes with a four-side seal and a right angle packing bag. Businesses may increase output while accommodating different wet wipe sizes because to its clever operation and customizable mould. Customization and adaption to various packaging requirements are made possible by the variable output options and adaptable non-woven fabric folding characteristics. The alcohol swab pads’ quality is maintained by the twice-heated sealing process, which guarantees safe and leak-proof packaging. Businesses may streamline their production procedures, cut expenses, and provide their clients with high-quality alcohol swab pads by selecting the VIPPAI VPD-250D alcohol swab pad machine. If searching for superior 4 side seal packaging machines and automatic packaging solutions, click here to learn more!